The question mosty asked is Are All American Force Wheels Forged? When it comes to high-performance wheels, American Force stands out as a premier brand in the automotive aftermarket. Known for their aggressive designs and unparalleled strength, American Force wheels are a popular choice among truck, jeeps and SUV enthusiasts. This commonly asked question that arises in the community is whether all American Force wheels are forged. In this post, we’ll explore the manufacturing processes, advantages, and specifics surrounding American Force wheels, particularly focusing on the fact that all American Force wheels are indeed forged.

Understanding Forged Wheels

What Are Forged Wheels?

Forged wheels are manufactured from a solid block of aluminum, typically 6061 aluminum, which is known for its strength and lightweight properties. The process involves heating the aluminum and applying pressure to shape it into the desired form, followed by CNC (Computer Numerical Control) machining for precision. This method results in a wheel that is denser and stronger than its cast counterparts.

Advantages of Forged Wheels

- Strength: The forging process produces a material that can withstand higher loads and impacts, making it ideal for both off-road and performance applications.

- Weight: Because forging requires less material than casting, forged wheels are generally lighter. This reduction in unsprung weight can lead to improved handling and acceleration.

- Customization: Forged wheels can be tailored to meet specific design preferences, allowing for unique styles and finishes.

- Durability: The dense structure of forged wheels makes them less susceptible to bending or cracking, ensuring longevity even under rigorous conditions.

Disadvantages of Forged Wheels

- Cost: The manufacturing process for forged wheels is more complex, making them more expensive than cast wheels.

- Limited Availability: While American Force offers a wide range of designs, the options available in forged formats may be fewer compared to cast wheels.

The American Force Brand

American Force Wheels is a well-respected name in the wheel industry, established with a focus on high-quality craftsmanship and innovative designs. Based in York, South Carolina, American Force has built a reputation for producing wheels that blend performance, durability, and style.

Manufacturing Excellence

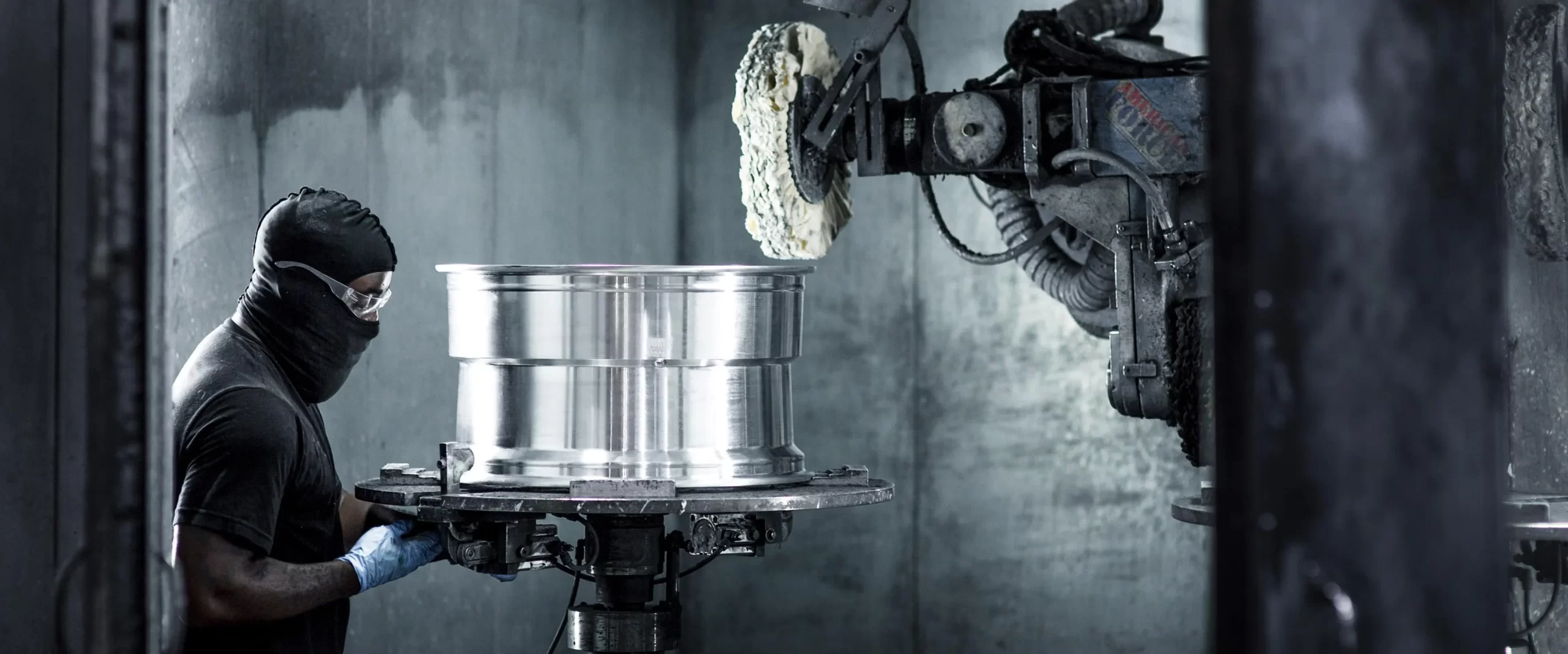

American Force prides itself on its state-of-the-art manufacturing processes. Each wheel is crafted using advanced software and CNC milling techniques, ensuring precision and consistency. The use of a solid block of 6061 aluminum as the raw material further enhances the wheels’ strength and performance characteristics.

The Forging Process at American Force

- Material Selection: American Force uses high-grade 6061 aluminum, known for its excellent strength-to-weight ratio.

- Heating and Pressing: The aluminum is heated and then pressed into a mold using both heat and pressure. This step is crucial for aligning the grain structure of the aluminum, which contributes to the wheel’s overall strength.

- CNC Machining: After forging, the wheels undergo CNC machining to achieve precise dimensions and intricate design details. This process allows for a high level of customization.

- Finishing Options: American Force wheels can be finished in various ways, including mirror-polished aluminum and vibrant color-matched candy finishes. This attention to detail in aesthetics complements the wheels’ performance capabilities.

Quality Control

To ensure that every wheel meets stringent quality standards, American Force conducts rigorous testing and quality control checks throughout the manufacturing process. This commitment to quality translates into reliable products that perform exceptionally well in various driving conditions.

Are All American Force Wheels Forged?

Are All American Force Wheels Forged? Yes, all American Force wheels are forged. This is a defining characteristic of the brand and what sets it apart in the competitive wheel market. Unlike many other manufacturers that offer both forged and cast options, American Force focuses exclusively on forged wheels. This specialization allows them to maintain high standards of quality and performance across their entire product line.

Why Choose American Force Wheels?

Choosing forged wheels from American Force offers several benefits:

- Performance Enhancement: The lightweight nature of forged wheels contributes to better handling and acceleration, making them an ideal choice for performance enthusiasts.

- Aesthetic Appeal: With a wide range of designs and finishes available, forged American Force wheels can significantly enhance the visual appeal of your vehicle.

- Long-Lasting Durability: The strength of forged wheels means they can withstand the rigors of off-road driving without bending or cracking, providing peace of mind for adventurous drivers.

- Tailored Fitment: American Force wheels are available in various sizes and configurations, ensuring compatibility with a wide range of vehicles.

Customer Experiences

Many customers who have opted for American Force forged wheels report high levels of satisfaction. Common themes in reviews include:

- Performance Improvement: Users frequently mention noticeable enhancements in handling and stability after upgrading to American Force wheels.

- Visual Impact: The unique designs and finishes of these wheels receive high praise, often being described as a centerpiece of the vehicle’s aesthetic.

- Strength and Reliability: Customers appreciate the durability of forged wheels, especially those who drive in challenging conditions.

- Excellent Customer Service: American Force is known for its responsive customer service, assisting buyers in selecting the right wheels for their needs.

Comparing Forged and Cast Wheels

To further clarify the distinction, let’s compare forged and cast wheels in terms of their manufacturing processes, strengths, and weaknesses:

| Feature | Forged Wheels | Cast Wheels |

|---|---|---|

| Manufacturing Process | Created from a solid aluminum billet | Made from molten aluminum poured into molds |

| Strength | Higher strength-to-weight ratio | Generally weaker, more prone to bending |

| Weight | Lighter, enhancing performance | Heavier, which can affect handling |

| Cost | More expensive due to manufacturing complexity | More affordable, ideal for budget-conscious buyers |

| Customization | Highly customizable | Limited customization options |

| Durability | Excellent, less prone to damage | Moderate, can be susceptible to cracks |

Conclusion

Concluding if are all American Force wheels forged the anwer is yes indeed forged, a fact that underscores the brand’s commitment to quality and performance. By focusing exclusively on forged wheels, American Force has established itself as a leader in the aftermarket wheel industry, offering products that not only look great but also perform exceptionally well.

If you’re considering upgrading your vehicle’s wheels, choosing American forged wheels means investing in a product that combines strength, durability, and aesthetic appeal. With various designs and finishes available, American Force wheels can elevate your vehicle’s performance while making a bold statement on the road.

Whether you’re an off-road enthusiast or someone looking to enhance your daily driver, American Force forged wheels are a reliable and stylish choice that will serve you well for years to come. Choose American forged wheels for your next upgrade and experience the difference in performance and style!